The Factory OS

A software platform that connects people, machines, and processes to meet the dynamic needs of 21st-century hardware development, production, and operation.

At First Resonance, we are building the ION Factory OS to empower the next generation of hardware development.

Hardware manufacturing is the bedrock of our society. Everything from automotive and air transport, energy, consumer goods, medicine, and much more is manufacturing. Despite the focus being taken away for the past few decades, these things did not become less important. We interact with them every day. And now, the great challenges of the 2020s are in addressing climate change, energy, new forms of sustainable transportation, and promoting the use of robotics to create safer work and lifestyles by reducing stressful and rote labor. To take on these new challenges, companies new and old need new methods of building. These methods are rooted in more flexibility, more automation, and a freer flow of data.

In isolation, all of these things sound good; however, we have found that existing systems claim flexibility, traceability, and collaboration, but they do very little to actually deliver on those claims. We believe that is because these systems were built in a fundamentally different time — a time when factories were not connected and people were not interacting with software on a daily (or minutely) basis.

A Factory OS fixes this. Below, we discuss the history of how existing manufacturing software solutions came to be and what has changed to necessitate a more connected Factory OS workflow. Then, we look at how a flexible, modular, and connected approach of a Factory OS enables the next generation of manufacturing. Finally, we will discuss how a Factory Operating System enables the evolution of society in the 21st century and how making the companies and people building hardware faster, more flexible, and more connected enables entirely types of product categories and workflows.

History

It would not do it justice to repeat the full history of 20th-century industrialization here, so the following is a very brief summary.

The steam engine created a new relationship between people and machines. Given new energy sources and locomotion, people started building more machines and larger machines. This continued rapidly through the 20th century, and humans revolutionized its relationship with the physical world. We got airplanes, automobiles, fighter jets, aircraft carriers, cranes, skyscrapers, and more. We did all of this with a relatively big tolerance for failure. The wars of the mid-20th century were industrial wars, and the military required tight controls on quality. As we had matured the inventions of the 20th century, hardware and manufacturing problems were really quality problems. Thus, we got Six Sigma, Lean, PFMEA, and other manufacturing process control and quality standards.

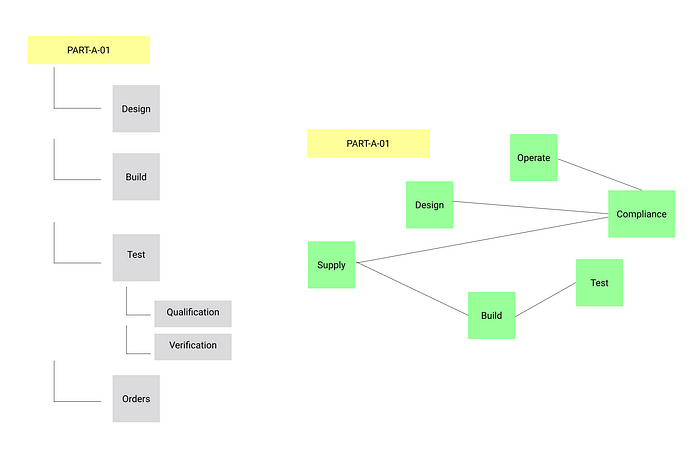

Hardware invention was taken over by quality control. We built more things, more reliably. The innovations in hardware manufacturing became quality and process control. Compute became more available, but was nowhere near as prevalent as it is today. So computer software was created to help administer the workflows for hardware production and process control, including factories. This is what these systems looked like:

These systems were created to administer complex factories by sitting alongside the factory (usually from a management or engineering office). People entered data to keep them up. Functions across large manufacturing enterprises all had their challenges to solve, so each got their own systems. Sometimes, they connected to one another, but in most cases, this was very manual and costly. Furthermore, they were still disconnected from factories and the people in them. Specifications like ISA-95 were created to define how information should move, given this inherent disconnect from the actual processes.

The Information Era

The world changed as the Internet came online in the 90s. As more systems became connected, information flow became faster and abundant. The industrialized world started transitioning to an information-industrialized world. More information flow allowed for globalization, and through policy and politics, manufacturing and hardware production also globalized. We will hold the discussion around the social and environmental impacts of producing goods and creating a global transportation supply chain powered by fossil fuels and exploited labor.

While the world connected through information, manufacturing spread out and continued the process control and optimization trends from the 20th century. “Automation” really meant even more control and refinement of processes. Consumer electronics manufacturing miniaturized and made breakthroughs for consumer applications, but other types of manufacturing didn’t adapt.

Meanwhile, technology progressed rapidly in software and connectivity. A few major themes emerged:

- Mobility: Compute is now everywhere. What used to be something you had to secure processing time for is not in everyone’s pocket. You can take compute everywhere, and the number of devices each person has continues to increase.

- Connectivity: In just a matter of 2 decades, people went from paying roaming charges to being able to connect from across the country and the world.

- Software and APIs: Software interfaces with standard interfaces and APIs to amplify the connectivity mentioned above have been powering a complex supply chain of information and workflows. The step functions in productivity have enabled software developers to build things like ridesharing apps that are actually a global-scale transportation network. By using telecommunications APIs, cloud computing, and other technologies, entire industries were disrupted in a few short years.

- Speed: People expect things faster than ever. Everything has become faster, including the speed to access information. Whereas some information used to be impossible to obtain, it is now a simple Google search away. Any and all information is at everyone’s fingertips.

- Software innovation timelines: Compounding the above points, it’s no surprise that software development and innovation timelines have become extremely fast. The amount of tooling to not only speed up development but also to improve its quality management through automated continuous integration/continuous deployment (CI/CD) systems, application performance monitoring (APM), and much more has allowed software developers to keep focus on innovation rather than the underlying systems necessary for global-scale software deployment. What used to take a team and millions of dollars of equipment can now be done one developer in a garage for dollars of infrastructure spend.

These changes compounded and transformed the world. This is the world we all live in now. The amazing thing is how quickly all of this happened. In some ways, the speed at which the Information Era changed our lives is similar to the speed the Industrial Era changed lives in the 20th century. To those working in manufacturing, however, these Information Era developments do not come with them into the factory. Outdated policies, an industrial sector overly dependent on a military-industrial past, and offshoring are just a few of the reasons as to why the factory has not evolved like the datacenter has.

That said, technology evolution is now pushing factories to adopt. Secure and reliable cloud infrastructure, a need to bring automation online to meet the demands of shifting supply chains, geopolitical pressures, and most of all, a need for people who grew up in the Information Era to be able to function in their daily lives mean that a new approach is necessary to power the endeavors of the coming decade.

The Factory Operating System

A Factory OS is a software platform that connects people, machines, and processes to meet the dynamic needs of 21st-century hardware development, production, and operation. It is built to adapt to the foundational changes above. Given the enormity of the changes in connectivity, mobility, modularity, etc. it is not enough to incrementally update software that was designed to administer factories and workflows. A Factory OS is a rebuilt workflow that assumes connectivity within a factory and between people and machines. Given its modularity and more sophisticated connection points, a Factory OS is better described through its principles rather than something specific. Below are those principles and relative comparisons.

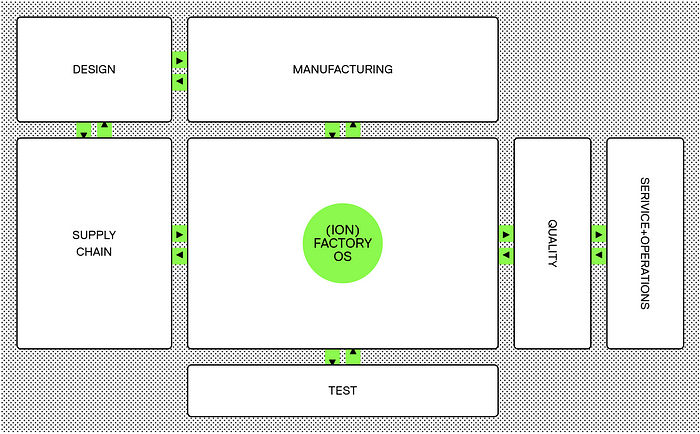

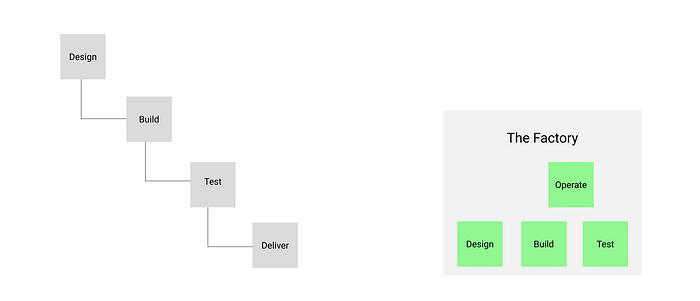

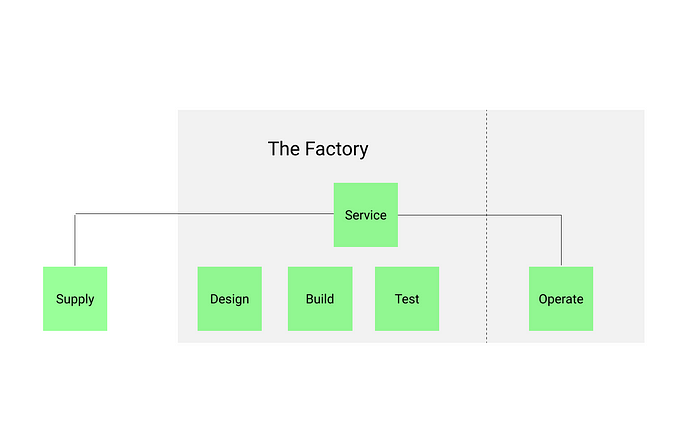

A Factory OS is made up of building blocks and not a left-to-right process.

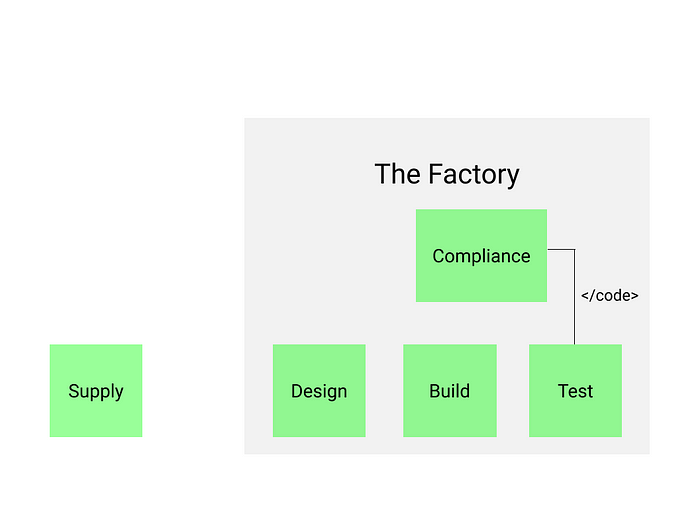

Each one of these building blocks is connected with interfaces that are accessible to developers and machines to extend the system to fit within complex operations.

This extensibility allows for embedded customizability and extensibility. The extensibility is infinite because of service-oriented architecture. Compared to existing systems, a Factory OS does not require massive amounts of specific customization, which can be very costly and take lots of time.

A Factory OS is built for collaboration, not centralization. While the appeal of a “central repository of information” can be appealing, we know that the most powerful systems are actually distributed. For example, git is actually decentralized while GitHub is more centralized that is compatible with the underlying decentralized system. A Factory OS can behave the same way. Decisions get made upstream in design and downstream at machines, while the Factory OS facilitates that interchange.

A Factory OS maintains a graph of manufacturing data, with interconnected traceability up and down the process. This graph of information allows people to quickly move through interconnected information to find the information they need very fast. In a world where things are moving very fast and there is constant change, this graph of information is far superior to a chained series of processes. A part progressing through a process limits modern hardware development that is linked through multiple complex processes and non-linear workflows. A Factory OS allows people to understand how parts have moved through a system and which processes have been involved over the course of time. A Digital Thread is a bi-product of this approach.

Finally, a Factory OS scales beyond the initial manufacturing process of a hardware product. While legacy systems facilitate the completion of a process before a part is sold, a Factory OS maintains a record of manufactured parts even after a part leaves the factory. The factory then serves as a maintainer for the end-product. The APIs allow operational workflows (e.g. a car on the road, an airplane at the airport) to report back into the Factory OS. Whenever a part needs to be serviced, the factory can still serve as the maintainer of that part. The factory is not just where the part is initially built — it becomes the lifecycle partner for the hardware product throughout its entire lifecycle. This attribute of a Factory OS theoretically allows the movement from part production and destruction into one that allows the continuous servicing and maintenance of hardware — keeping cars on the road forever, keeping rockets launching/landing/launching, and ending the destructive cycle of production and waste.

The world changes with the Factory OS

We’re living in a time where there are fundamental shifts happening to core infrastructure. For example, Stripe is changing how money flows (and not just on the internet). GitHub has built a software supply chain that allows for entirely different interactions in how people collaborate with their expertise and build products.

The Factory OS is one of these changes. On the surface, it looks like it is an evolution that applies modern technologies like APIs, mobile apps, and microservice architecture. Actually, it’s an entirely new architecture for how software interacts with the builders of physical products. It is embedded into these complex environments, and it coordinates collaboration across sophisticated expertise in mechanical, electrical, and software engineering. It lays the groundwork for a software-defined process flow and material supply chain. It has the interfaces required to move quality control to data science workflows. It is extensible and empowers software developers to automate and extend the platform into the fabric of their innovations.

Software has enabled amazing advancement in software workflows. Today, technology is moving from digital interfaces and getting embedded into the physical world around us. The biggest challenges are in climate, energy, transportation, healthcare, space exploration and other areas where humans interact with the world around. With proven principles from the digital world now coming back out into the physical world, a Factory OS coordinates those types of interactions for people building in the physical world. It accelerates those workflows by removing the rigidity and control they once had to have on factory processes. The modular workflows enable people to execute faster, find information faster, explore data faster, and apply those learnings faster.

The Factory OS will allow engineers who have been constrained by systems and process control to resume the invention and innovation we had in the earlier parts of the Industrial Era. The Factory OS extends and allows connection to developments in the Information Era. This architecture, and the people it empowers, will accelerate our society’s rate of solving physical world challenges. People will be able to build, innovate, affect change, and invent new interactions with the physical world. The Factory OS is just the foundational layer. Like computer Operating Systems, much of the creation will happen on the Factory OS platform. As people now create music, art, decisions, games, and more on computer Operating Systems, people will build airplanes, cars, medical devices and more on the Factory OS. The OS is just the start.

First Resonance is leading the next industrial revolution with the ION Factory OS. ION is powering companies building electric airplanes, rockets, autonomous vehicles, 3D printing robotics, and more. It is used by manufacturers of all sizes — from fast-growing startups to Fortune 500s — to connect parts, complex supply chains, and advanced machinery. Manufacturers build with ION to solve the world’s biggest problems in climate, transportation, and energy.